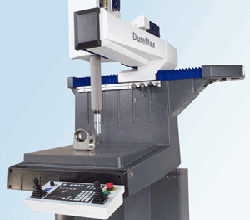

Machine specification

The right measuring equipment for the shop floor.

Replace complex gages: Typical everyday measurement tasks require several gages, multi-location measuring devices and manual inspection equipment. And when things change, investment in new equipment is needed. With DuraMax, these additional costs and time-consuming changes are no longer necessary.

? Seamlessly integrates into any production environment

? No measuring lab required

? Small footprint and easy set-up

? Temperature stability up to +30?C

? User-friendly CALYPSO CAD-based software

? Quick and accurate measurements with ZEISS VAST XXT scanning sensor

? Measuring range (in mm) 500 x 500 x 500

? Offers interface to Handysurf surface measuring instrument

? Does not require compressed air

? Faster, more accurate and reliable measuring

Replace gages and manual inspection equipment: The ability to measure quickly and accurately and the flexibility to react to changes is a must in the machining and tooling industry. Fixed gages and manual inspection equipment are no longer economical.

? Replacement for fixed, expensive gages

? Flexibility for workpiece changes and different measuring tasks

? Pays for itself in a very short time

? More effective and economical than gages

? Object-oriented programming allows for flexible measurement plans

Key Features

Made for production, DuraMax is a complete CNC CMM that offers temperature stability up to +30?C, passive vibration damping, needs minimal space, and is easy to set up. Its well-equipped standard configuration has ZEISS scanning with an extensive available stylus selection. It’s easy to use, it can be loaded from three sides, offers a practical stylus rack, has low space requirements to leave more room to work, and has an optional base for better positioning.

Machine Technology

DuraMax has a very reliable drive system with completely covered guideways, an integrated damping system, and compensation of guideway errors (CAA corrected). It is a complete ZEISS system with our technology, including the C99 controller, our VAST XXT scanning sensor, and CALYPSO measuring software. And it’s easy to install, since it is ready to use and offers fast startup, and needs no special installation or power requirements.

VAST XXT scanning? ? ? ? CALYPSO software ? ? ? ? ? 500 x 500 x 500 range

VAST XXT scanning sensor

Measure quickly and accurately with VAST XXT scanning. No other CNC measuring technology is as reproducible and delivers such precise information on size, form and position. No other measuring method delivers results as fast.

? Probe for single-point measuring and scanning

? Stylus receptacle for CNC-guided stylus change, for 3, 6 or 9 styli

? Adapter plate with 25 mm diameter for optimal reproducibility

? Stylus system length: 30-125 mm axial, up to 40 mm radial

? Large deflection range (?3 mm) for maximum collision protection

? Lowest measuring force for a wide range of workpieces

CALYPSO Software

CALYPSO is based on the principle of visual metrology: measure what you see ? without extensive programming or complicated code and text input. All part features from a drawing or a CAD model are stored as icons. Select the icons you need and your measurement plan is finished. CALYPSO automatically calculates the ideal measuring run and travel paths.